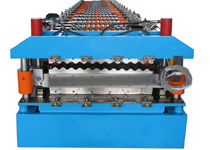

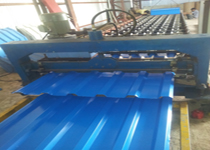

Roofing Sheet Making Machine

We provide you the fully automatic T Bar Roll Forming Machine with punching of T-bars in the various models and Forming sizes. Our manufacturer is one of the earliest one in India to develop the main T grid roll forming machines. So we have ability to design custom t grid roll forming machines according to customer sample or profile drawings.

- D coiler 500 Kg. cap.

- Entry Gate with

- Roll Forming Line with 20station , 5 Gear Boxes & 8 H.P. electrical.

- Control Panel auto

- Cutting Unit (hydro. )

Technical Specifications

- Maximum sheet width that can be formed : 100 mm

- Maximum sheet thickness in Strips that can be formed : 0.6 mm

- Horizontal distance between shafts : 200mm

- Number of forming stations : 16 + 5 nos.

- Vertical station : 6 nos.

- Total HP for Line : 5 + 3

- of the machine : 4 mt/minit

- Size of machine : 2500 x 900 x 1000 mm + 1500x900x1000mm

Mandrel Uncoiler

- Coil weight : 500 kg Max

- Coil width : 150 MM

- Coil bore : 470 MM min, 520 MM max dia.

- Mandrel movement : manually

Entry Gate

Entry gate will be provided for movement of sheet to roll former.

Main Base

The main base is MS fabricated structure and adequately ribbed to minimize the distortion. It is accurately machined on top and bottom surfaces the threaded holes are made on the bed for positioning the stands.

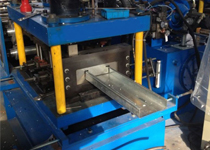

Mill stands (Station)

The stands are mounted on the bed of the machine the line alignment can be easily done due to guide ways arranged on the bed of the machine. Each forming head consists of a fixed housing and sliding type out board housing. The mill stands will be arranged to locate shafts mounted on taper bearings. For the top shafts the bearings are housed in the cartridge type bearing blocks. The bottom shaft bearings are located in the bored machined in the housings. The bottom arbors are fixed in position whereas the top arbors along with cartridge blocks could be raised or lowered in vertical guides machined in housings.

Roll shafts

The roll shafts dia. 45mm will be manufactured from quality steel and will be keyed to locate tooling.

Drive

The drive to the roll former will be by means of a gear box system. The main drive will be provided by means of 8 HP motor

Tooling

One set of Tooling with WPS grade will be from imported material suitable for your machine as standard supply. The same is involved in operations like rough machining, keyway, rough profiling, profile machining, hardning and inspection with final template for above.

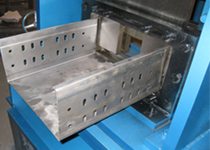

Cutting Unit (Hydraulic.)

Cutting press with dais

- Line sequence

- D coiler

- Feeder

- Forming

- D coiler

- Forming

- Cutting