Gurukrupa Industries

Address : Gondal Road Chowakadi, Near Ashok Leyland Show Room, Opp. Pooja Sales, Rajkot - Gujarat(India)

Mr,Jadeja

(+91-9601155559)

Product Range

Products Gallery

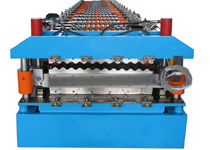

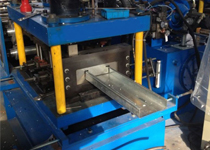

Gurukrupa Industries, Was established in 2008, acts as a metal roll forming machine design, Develop and roll former manufacturer for customized Roll Forming Machine located in Rajkot. We offer various type of roll forming machines and earn a worldwide reputation of producing quality roll forming machine equipment to meet our clients’ requirement. Our vision is to achieve global leadership in providing value-added high quality solutions to our clients in utilizing by combining technology expertise, production skills, process focus and a commitment to build long term business relationships with our client.

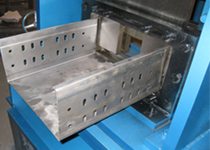

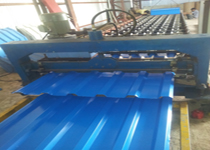

Roll forming Machine is a continuous Sheet metal forming process where in the flat metal coil strip is passed between successive pairs of roller i,e Top/Bottom or even side rollers in order to get the desired cross section.

Roll forming Machine is a continuous process for forming sheet, strip or coiled metal stock into long shapes of basically uniform cross-section. The material is fed through multiple pairs of contoured forming rolls, which progressively shape the metal until the desired cross section is produced. Roll forming finds wide application in real estate, building, construction, office furniture appliance and many more. A Roll Forming Machine can be formed any type of ferrous and non-ferrous material. MS and aluminum are the most common materials used in the roll forming machine process. Stock to be roll formed post-cut afterwards to a specified dimension, with the latter being most common. The more productive post-cut method typically involves a stock de coiler, a roll forming machine, a cutoff machine, and a run out table. Production speeds average 8 to 12 meters per minute

Roll forming Machine dimensional tolerances are depending on stock Material width and thickness, Roller material, the quality of the tooling, machine condition, and Roll Forming Machine operator skill. Cross section Dimensions are commonly held within plus or minus .010 to .030 of an inch, or .25 to.78 of a millimeter